Cable Car Radio, Cities

New Ropes Monitored by AI: Visual defect detection

SI: Mr. Smetana, TEUFELBERGER-REDAELLI is a well-known company, but how is it positioned in the market today?

Mr. Smetana: Well, the company has been active on the market for about 200 years. Not quite that long with high-performance steel ropes, but that is also one of our core competencies. We supply the entire cable car industry, and I would say that from today’s perspective, we are very successfully active in the market.

Could you tell us about new Alliance for Intelligent Rope Monitoring? What is it intended for?

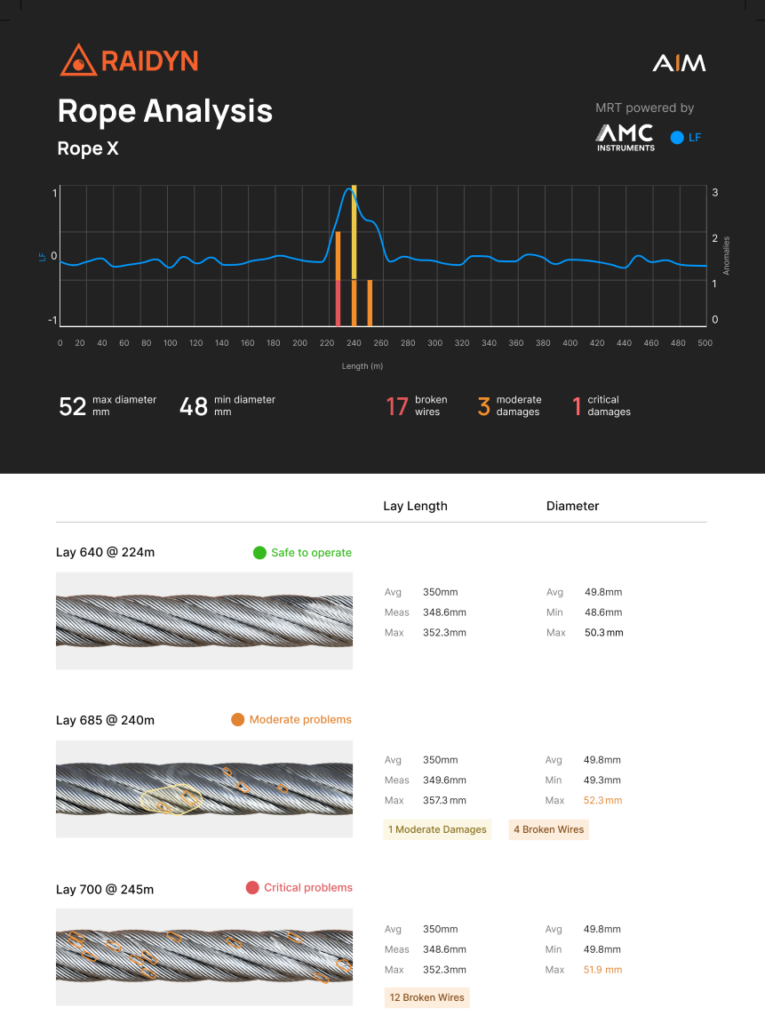

The Alliance for Intelligent Rope Monitoring is an alliance we founded together with two partner companies. One is Raidyn, a company specializing in software solutions, applications, and algorithms. The second company is AMC Instruments, an Italian company that is part of an American corporation. They specialize in magnetically inductive testing equipment.

Together with these two companies, we formed an alliance and developed a tool that provides an all-in-one solution for continuous rope monitoring. This is not just magnetically inductive testing – essentially checking how many wire breaks are present in a rope at a given point in time – but also visual defect detection.

It covers everything related to corrosion, wire breaks, damage, lightning strikes, etc. And this is actually new to the market.

On one hand, it combines the functional and physical devices, and on the other, it uses AI algorithms through a 360-degree camera. This allows the tool to automatically detect and classify defects for the user at the user interface. Anomalies are categorized as critical or non-critical, enabling operators to see at any moment the condition of a rope, whether it has defects, whether maintenance is required, and how the rope’s lifespan is developing.

AIM The tool enables real-time detection of damage:

wire breaks, corrosion, geometric deviations, and more.

Why did you develop this? Why is it needed?

Until now, there have already been tools on the market that check the lifespan of a rope, essentially, measuring how many wire breaks a rope has at a certain point in time and predicting how it will develop over its lifespan. These tools evaluate the rope and generate reports.

What has been missing until now is visual detection. Especially for installations in urban areas, which run 24/7 – so to speak – and where the service personnel may either not be sufficiently trained or not even available, there is a need for operators to see at any moment whether there is a critical situation with a rope. And this information should be provided automatically.

This is exactly the direction of our innovation.

When is this system interesting for alpine ski resorts?

It can, of course, also be interesting for alpine ski resorts, especially for installations that are heavily used and whose feeder lifts operate for many hours.

In addition to the regular inspection intervals required by authorities, operators can get a better, continuous overview of the rope’s condition – not just in terms of wire breaks, but also diameter, strand length, corrosion, and other anomalies. This allows the operator to better assess when early maintenance is needed and plan accordingly.

So this is also about the rope’s entire lifespan and the associated costs?

Exactly. That’s the second aspect. We also have our second product innovation, the Solitec ® XD rope. With this, we are closing a gap that existed in our portfolio until now.

In urban areas, there are specific requirements for lower noise emissions, reduced vibrations, and extended rope lifespan. Previously, we did not have a dedicated product addressing these needs. With the Solitec ® XD, an evolution of our Solitec technology, we are now entering this market segment.

Longer lifespan, less noise, reduced vibration:

With the new Solitec® XD cable car rope, manufacturer TEUFELBERGER-REDAELLI is setting new standards in urban environments.

To what extent do you offer a service covering the entire lifespan of the rope?

Our service begins even before the customer inquiry, meaning we provide technical consultation on rope design and route planning.

Then it moves into the tendering process, supporting customers with all aspects of bidding and proposals. Once the order is confirmed, we manage the delivery phase. This includes everything from organizing transport with shipping companies to checking delivery routes.

We also offer the installation of the rope itself through collaboration with partner companies. The rope splicing comes from our own facilities, with two splicing teams in Italy and Austria, covering the global market.

Finally, our aftermarket service covers everything related to rope maintenance: shortening, renewing splice areas, lubrication, or other issues. We also provide, upon customer request, rope analysis at interaction points in the installation, such as towers and sheaves, using our in-house developed devices.

On one hand, we have the tool, which measures rotation and vibration along the entire rope length. On the other, the Geometric LED Detection system measures four geometric parameters: diameter, waviness, quality, and strand length. This allows us to give customers a very accurate understanding of the rope’s condition, performance, and development in their installation, and advise on necessary adjustments.

And this probably brings us full circle back to what we discussed at the beginning.

Exactly. That’s where the circle closes. The device we are presenting now is, in its current form, a prototype. We have already installed it at a facility in San Martino di Castrozza for initial testing. Of course, we will continue to engage with customers in the market, bring them in as lead users, and develop it to full series production.

What it offers is this: magnetically inductive testing for wire breaks, a 360-degree camera for visual defect detection, and parameters normally monitored through building or rope management systems (such as diameter and strand length) are also captured visually. In the end, it combines three functions in a very compact space – something that hasn’t existed before.

It uses AI algorithms that continuously and constantly learn from defects. In our view, this makes us “fit for future.” And innovation? It’s happening right now.

Transparency Notice:

This article is an edited transcript of the German-language podcast Bergdialoge.