Cities, Tourism

Poland: Urban compact cable car gets a makeover

Bridge or tunnel – these are usually the only options when it comes to crossing a river. But not in Wrocław, Poland: there, the Technical University opted for a compact cable car.

Since 2013, the “Polinka” has connected the new campus on the west side of the Oder River with the “old” university grounds on the east bank.

Busiest compact cable car

Of the 32,000 students and 4,200 staff, up to 2,100 use the Polinka daily. In addition, around 900 tourists and local residents take advantage of the ride on INAUEN-SCHÄTTI’s compact cable car.

Over twelve years, this has added up to roughly 500,000 trips – an average of 114 trips per day.

“The Polinka is the busiest compact cable car we’ve built, which made the 2025 revision project especially exciting for us,” says Johann Schiesser, Technical Officer for Service & Maintenance of Cable Cars at INAUEN-SCHÄTTI.

The Swiss company specializes in managing every stage of a (compact) cable car’s lifecycle – from planning, design, and construction to maintenance, service, revisions, and, if necessary, decommissioning.

Very good overall condition

Given the high usage of the cable car, Schiesser was impressed by its excellent overall condition: “Maintenance has been handled by DOPPELMAYR Poland since the system was rebuilt. Despite the heavy use, the installation was very clean and well maintained, and wear was minimal.”

Still, the standard six- and twelve-year revisions needed to be carried out – and for that, INAUEN-SCHÄTTI AG, the compact cable car expert, was brought in.

Johann Schiesser managed the planning and project coordination from Switzerland. He organized spare parts logistics, the transport of tools (such as hoists and cable drums), and handled customs formalities.

On site, a service technician supervised the work for a month, supported for two weeks by two cable specialists.

At all times, staff from DOPPELMAYR Poland and the operator assisted with the project.

The cable car operator, DOPPELMAYR Poland, and INAUEN-SCHÄTTI worked hand in hand to carry out the major overhaul.

Extensive revision work

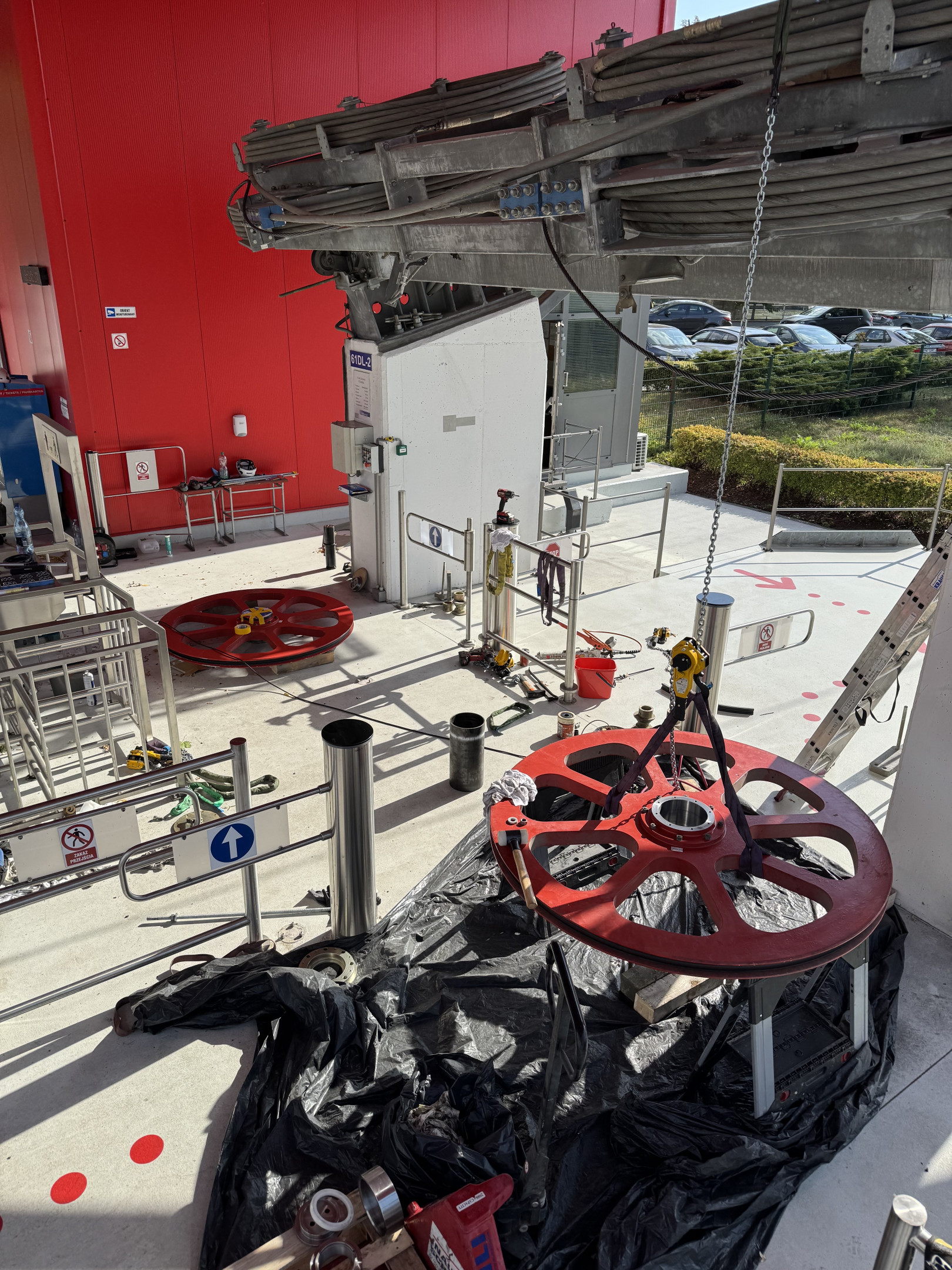

In the first step, the drive units were dismantled and taken apart. “Fortunately, we found a Polish company that sandblasted, magnetically tested, and repainted the parts for us,” emphasizes Schiesser.

Meanwhile, the team overhauled the rope saddles on the towers as well as the sheaves in the stations, performing magnetic inspections on the components. A Polish expert was brought in to assist with this process.

The insert ropes in the sheaves were also replaced, after which the drive units were reassembled.

Rope work included

“As part of the major overhaul, we also pushed the carrier ropes and replaced the haul rope. The old rope had reached the end of its service life due to heavy use,” says Schiesser.

The new 20-millimeter haul rope was spliced by an expert from the manufacturer FATZER together with the entire team. Finally, the fully overhauled cabins were installed.

Deadline for the semester start

“Despite the extensive work, we were able to complete the revision within four weeks, working closely with all helpers – and still had some buffer time,” reports Schiesser.

The deadline was set to coincide with the start of the university semester. Without the cable car, students and staff would have faced a twenty-minute detour across a bridge, disrupting teaching and research activities.

“The compact cable car system really helped here. Its compact design also keeps maintenance manageable,” says Schiesser. With this major revision, INAUEN-SCHÄTTI has once again gained valuable experience.

Technical data:

15-ATW Polinka, Wrocław

| Height of drive dtation: | 119,00 m |

| Height of the return station: | 119,70 m |

| Height difference: | 0,70 m |

| Inclined length: | 373,19 m |

| Towers: | 2 |

| Cabins: | 2 |

| Cabin Capacity: | 15 P/ 1.200 kg |

| Max. Speed: | 5 m/s |

| Travel time: | 1,95 min |

| Capacity: | 366 P/h |

| Investment (2013): | €3 million |