Digitalisation & Innovation, SI World 2/2025

Alpine innovations: smart solutions for ski resorts

Autonomous ropeway operation Whether for gondolas, chairlifts, or aerial tramways – DOPPELMAYR’s autonomous operation system AURO is steadily gaining ground in the industry.

AURO ropeways operate without station attendants, with cameras and sensors ensuring smooth processes and continuous monitoring, especially during boarding and disembarking.

The AURO system autonomously identifies irregular operating situations and either shuts down or slows the installation automatically.

In case of a malfunction, the system is supervised by an operator in the Ropeway Operation Center, who can intervene when needed. This synergy between human expertise and advanced technology enables rapid responses to shutdowns and ensures high availability of the ropeway.

ROPERA®

promises benefits for both passengers and operating personnel.

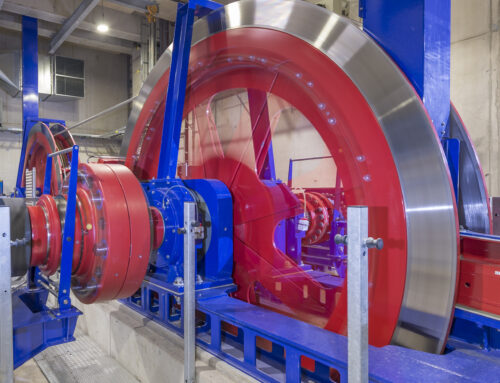

New standard for monocable ropeways

The South Tyrolean ropeway manufacturer LEITNER presented in May 2025 ROPERA® – the new standard for monocable ropeways. ROPERA® combines proven components, such as the LEITNER DirectDrive gearless drive technology, with new developments that help offer customers an optimized product in terms of cost-efficiency and resource conservation.

The noise sources are optimized throughout the entire system. This includes the use of sound-insulating and decoupling elements near the horizontal and vertical rope deflections, fewer rollers for horizontal rope deflection in the return station, and a larger sheave to reduce vibrations and ensure smoother operation.

In addition, the tensioning carriage is mounted with acoustic decoupling, further minimizing noise. The new standard also includes innovations that make daily operation easier for customers.

These offer folding platforms, two-level working platforms, a spacious platform in the front station area, transparent plastic covers for the tyre conveyors and improved accessibility to all station components.

Heavy-duty drones are intended to reduce snowmaking costs.

Snowmaking with drones

The Swiss lance specialist BÄCHLER tested an innovation that redefines the aerial transport of snow lances. Heavyduty drones are intended to reduce snowmaking costs and make the process more sustainable. The company has successfully completed test flights with loads of up to 40 kilograms.

Due to the current limited payload capacity, only parts of a snow lance were lifted. The advantages of such a system are significantly lower costs, no terrain damage, reduced environmental impact, and sustainable operation thanks to electric motors.

And 40 kilograms is far from the limit – BÄCHLER expects that regulatory hurdles will be cleared to allow flights with drones carrying up to 100 kilograms.

AI-powered rope monitoring

TEUFELBERGER-REDAELLI introduced the “Alliance for Intelligent Rope Monitoring” (AIM) this year, a collaboration with AI specialists Raidyn and rope monitoring experts AMC Instruments.

The three companies developed a web-based, real-time monitoring tool for ropeways, combining MRT technology with AI-driven visual defect detection. AI detects pitch, diameter, wire breaks, and corrosion, while AMC Instruments provides the carrier medium to examine the rope‘s interior.

Real-time rope monitoring

This trend is also confirmed by rope manufacturer FATZER, whose Smart Service combines hardware and software to help ropeway operators plan maintenance and identify potential issues.

At the core is TRUcockpit, a digital rope twin developed by TRUcompany, a joint venture of FATZER and GRÜNENFELDER & PARTNER.

TRUcockpit centralizes all documentation, maintenance records, and rope inspection reports, allowing operators to access rope history and splice information. Using TRUscan (magnet-inductive testing), operators can monitor rope condition independently of official inspection intervals, detecting anomalies early.

Rubber tracks

prevent damage caused by traditional aluminum or steel tracks.

Rubber tracks for large snow groomers

The snow-poor winter has shown that snow groomers increasingly operate on thin snow or even grass, risking damage to both terrain and machines. To address this, HANS HALL introduced rubber tracks, which were tested this season in their largest version yet, with a working width of 4.2 meters.

The long-term tests proved that rubber tracks prevent damage caused by traditional aluminum or steel tracks, which can tear thin snow layers and leave brown spots or holes.

Rubber tracks press the snow rather than throw it, allowing snow-free areas to be traversed without harming the ground or spreading dirt.

While rubber tracks have long been used on smaller machines, the Fishbone Alpine Grabber is now available with a 1,600 millimeter track width, making it suitable for large snow groomers such as the PRINOTH Leitwolf or the PistenBully 600 and 800 from KÄSSBOHRER.

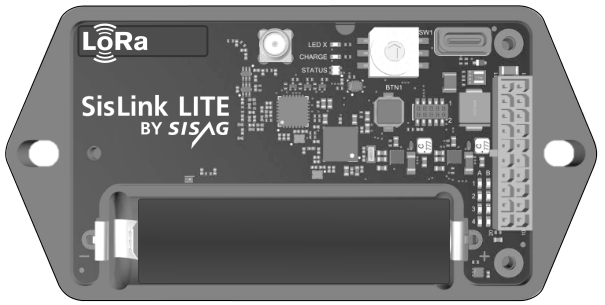

SisLink

delivers guest information directly into the cabins – with minimal infrastructure.

Guest communication tool

SisLink, a tool that simplifies passenger communication along ropeway line, was presented by SISAG. Using the low-energy LoRa standard, it automatically broadcasts pre-recorded multilingual messages directly into cabins in case of disruptions – triggered by the ropeway control system.

The LITE version operates on a small battery without the need for solar panels, while the PR version adds WiFi/GMS and multiple audio/video interfaces, enabling advanced features such as targeted incabin advertising.

Cost-efficient reservoir circulation

DEMACLENKO, in collaboration with OLOID Engineering GmbH, has introduced a new solution for circulating and aerating water reservoirs used in snowmaking. The OLOID technology provides water mixing while consuming less energy and requiring little installation effort.

The device is mounted on a floating platform, placed directly on the water surface, and automatically adapts to changing water levels, making it suitable for both new and existing reservoirs.

OLOID technology

helps to circulate and aerate snowmaking water reservoirs.

At the core of the system is a mixer that generates flow and wave movements reaching down to the bottom of the reservoir. This ensures circulation and prevents the natural stratification of water layers, which typically complicates reservoir management.

In winter, the technology helps keep the water surface ice-free, while in summer it effectively suppresses algae growth and improves water quality. The OLOID system eliminates the need for compressed-air piping and compressors, thereby lowering investment requirements and minimizing maintenance.

By supporting stable water conditions throughout the year, the system not only enhances snowmaking efficiency but also extends the long-term sustainability of reservoir operations.