Cableway & Technology, SI-Alpin

Innovative energy system for cable cars uses braking energy

Since 1887, a funicular railway has been running from the city of Biel to the Juraanhöhe near Magglingen. The railway not only transports excursionists, it is also part of the public transport system with a dense timetable. In 2019, the railway was thoroughly overhauled and a large PV system (42 kWp) has recently been in operation on the roof of the mountain station.

It is the keystone of a new type of energy system that was developed at the Department of Engineering & Architecture at the Lucerne University of Applied Sciences and Arts and has proven itself in everyday operation in recent months.

Using braking energy for the next uphill run

The funicular consists of two carriages for 120 passengers each, which are connected by a haul rope. When one of the carriages sets off from the valley station, it needs drive energy to gain height. When it has covered more than half of the 1700 m long distance, no more energy is needed, because the downhill train and the corresponding traction rope are now so heavy that they pull the first wagon up.

The wagon travelling downhill now even has to be braked. The energy released in the process can be recovered (recuperated). In this way, the funicular railway constantly alternates between energy input and output.

A team of researchers from the Department of Engineering & Architecture at the Lucerne University of Applied Sciences and Arts has developed an innovative energy management system that controls the complex energy flows.

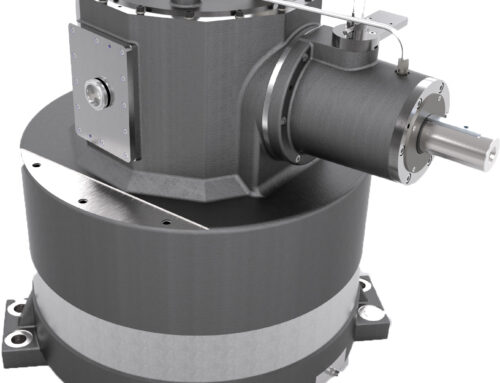

The braking energy is stored in a battery to be used a short time later to power the next ascent and the auxiliary operations (pumps, fans, heating). The battery also serves as a buffer store for the solar power.

“Thanks to the PV system and braking energy, the funicular can cover more than 30 per cent of its total energy needs itself,” says project manager Olivier Duvanel, who works as an electrical engineer at the Department of Technology & Architecture at the Lucerne University of Applied Sciences and Arts.

Innovative control of energy flows

Duvanel’s idea for the energy concept dates back to 2015. Based on extensive measurements, he drew up a feasibility study on technical implementation and economic viability.

Subsequently, the heart of the system was developed at the Digital Energy and Electric Power (Deep) competence centre of the Lucerne University of Applied Sciences and Arts: the energy management system that controls all energy flows of the railway, including the PV system and battery storage.

Over the past two years, the system was installed and optimally regulated in the course of the overall renovation of the funicular.

In mobile applications, the interaction of the electrical components places high demands that are not comparable with the PV system on a house roof. To master this challenge, Olivier Duvanel was able to draw on six years of practical experience in the cable car sector, which he brought with him when he moved into academic research six years ago.

Four fifths of the energy is used on site

In addition to the PV system, the battery with 68 kWh storage capacity is the central component of the energy system. It stores the recuperated braking energy until it can be used for the next ascent, as well as surplus solar power from the PV system.

In this way, more than 80 percent of the self-generated energy can be used for the funicular. Some of the stored energy is to be kept in reserve in the future so that the two carriages can be returned to the stations in the event of a grid failure. The diesel generator previously used for this purpose will thus become superfluous.