Cities, SI Urban 1/2021, SI-Alpin, Snowmaking & Slope Maintenance

New snow blower for cog railway

Manitou and Pike’s Peak Railway (also known as the Pikes Peak Cog Railway) is a standard-gauge cog railway in Colorado, USA. The line runs from Manitou Springs to Pikes Peak. With a route altitude of around 4,300 metres above sea level, it is the highest railway in North America and it tackles a gradient of 25 percent.

The railway near Colorado Springs has transported people up the mountain since 1891 and was closed temporarily at the end of the 2017 season. It is now undergoing complete modernisation and reopening is planned for the 130th anniversary, in 2021. Three new train configurations, each comprising a diesel engine and three carriages, were ordered from manufacturer Stadler in spring 2019.

The old, SLM twin units will continue in use and therefore need new cogs in the Strub system. In addition, the stations will be modernised and the rail infrastructure will be replaced. The investment volume amounts to 100 million dollars.

ZAUGG is also joining the party

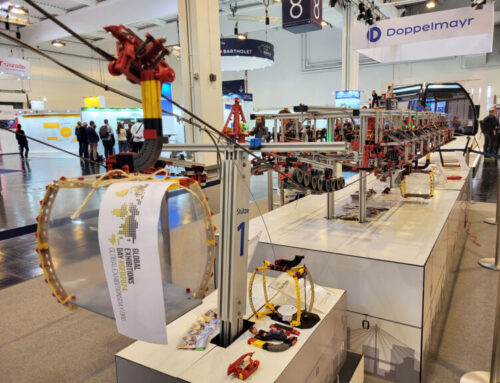

With the vehicles from Stadler, a snow blower will now also be supplied by Swiss manufacturer ZAUGG. To be precise, a pushed snow blower unit has been ordered, which is able to tackle snow drifts up to three metres high and six metres wide. This is also necessary on North America’s highest cog railway.

With a diameter of 1.2 metres, the two cutting reels at the front of the snow blower can cut through 3,800 tonnes of snow per hour and blow it 15 to 30 metres away.

The snow-clearing mechanism here is powered by a diesel hydraulic unit and the two cutting reels can be separately extended horizontally. Both reels are raised and lowered together. The two ejection chutes can direct the ejected snow independently of one another. Furthermore, a height-adjustable track plough can be fitted at the downhill end. A special cog provides additional braking power.

Swiss design and quality overseas

The snow blower will be controlled by the operator in the dedicated driver’s cab. This features a safe, ergonomic and comfortable working environment. Intuitive design and arrangement of the control elements help with operation.

In general, the snow blower is designed according to high, Swiss standards and equipped with advanced vehicle control systems and detailed diagnostic features. The snow blower will be pushed by the new Stadler engines; in clearing mode these will be controlled remotely from the driver’s cab of the snow-blower.

Technical Data

Snow Blower MPPR

| Gauge | 1435 mm |

| Power generation cutting reel | Diesel-hydraulic |

| Axle arrangement | 2 |

| Number of vehicles | 1 |

| Commissioning | 2021 |

| Seats | 2 operators |

| Length over coupling | 9840 mm |

| Vehicle width | 2700 mm (car body) 2950 mm – 5950 mm (snow cutting pods) |

| Vehicle height | 3875 mm (car body) 4165 mm (max. ejection chutes) |

| Wheelbase | 4000 mm |

| Carrying wheel diameter, new | 710 mm |

| Cutting reel diameter | 1200 mm |

| Ejection impeller diameter | 1000 mm |

| Snow clearing width | min. 3400 mm max. 5950 mm |

| Snow clearing height | min. 1750 mm max. 2850 mm |

| Snow clearing performance | Approx. 3800 metric ton/h |

| Ejection distance | 15 m – 30 m |