SI World 2/2022, Snowmaking & Slope Maintenance

Gamechanger energy efficiency

Sky-Rocketing power costs, a gas shortage, climate change: there are currently many factors forcing ski resorts to improve their energy efficiency. When it comes to snowmaking, the lances from BÄCHLER can help, as the Swiss manufacturer really puts energy efficiency into practice – and has done for many years.

Less compressed airand lower energy demand

In 2000 the engineers therefore not only pursued the concept of energy efficiency for the VANESSA snow lance; they also put it into practice with every fibre of their being.

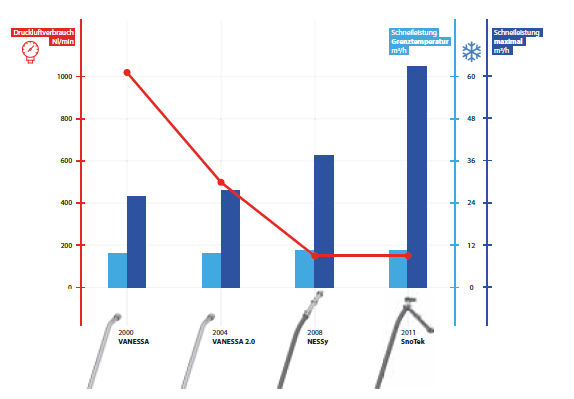

Whereas the HKD lances imported since the 1980s consumed 2,900 litres of compressed air per minute, the first in-house development, VANESSA, needed only 1,080 litres. Yet this was just the start of the journey towards even greater efficiency.

Bruno Koch, CTO bei BÄCHLER

Energy efficiency is the top priority for BÄCHLER CTO Bruno Koch.

150 rather than 1,080 litres of compressed air

In 2004, with a new nozzle shape, the snow specialists from BÄCHLER were able once again to halve the compressed air consumption of the VANESSA. Nevertheless, the greatest leap came with the NESSy technology, which enabled the engineers to lower consumption to 150 litres.

Physics sets limits

“Despite reducing the volume of air required, we were able to keep the snow volume within the marginal temperature range and even to increase it slightly – from ten to eleven cubic metres per hour,” Bruno Koch reports.

This is especially noteworthy, as the physical limits – according to current knowledge – are virtually exhausted in the phase when the snow begins. If the ambient air is no longer able to provide energy to convert water into snow or ice pellets, then the available natural resources are exhausted.

The multi-head technology offers an option here to increase the snow volume without disproportionate energy use. BÄCHLER is well known for offering a double and a triple option here.

Double head – double snow volume

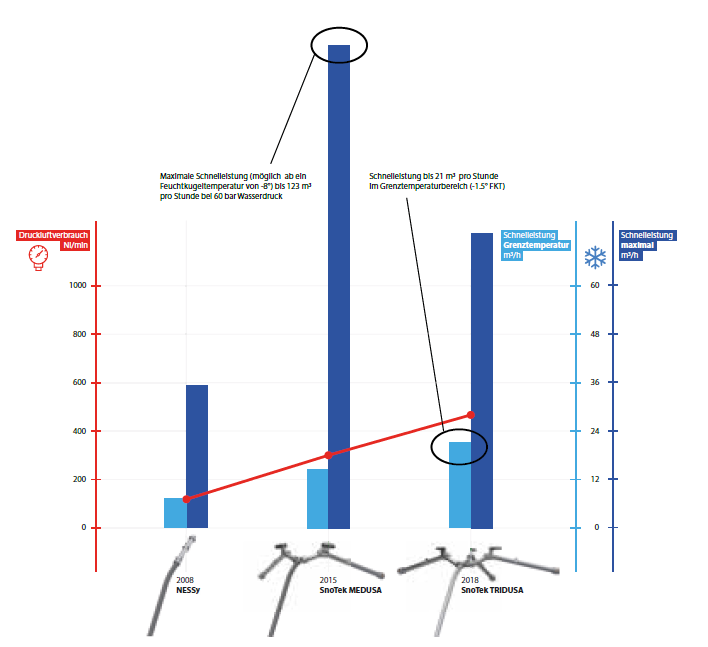

The Bächler SnoTek MEDUSA double-head lance combines the advantages of the energy-efficient NESSy technology with the additional power of the SnoTek modules for lower temperatures.

Consequently, with twice the air volume in comparison with a NESSy, the snow volume in the marginal temperature range can therefore be doubled. “The maximum output of the SnoTek MEDUSA becomes almost criminal.

From a wet-bulb temperature of minus eight degrees, it can be switched on fully and up to 900 litres of water per minute flow through the snow lance,” Koch highlights. With 300 standard litres of compressed air per minute, this allows a snow volume of 123 cubic metres per hour.

With the multi-head technology

the snow volume can be increased with proportionate additional energy consumption. As the slightly exaggerated scale shows, the double head ensures maximum snow output, whilst the strengths of the triple head are displayed in the marginal temperature range. The comparison in this graph is based on an optimised nozzle setting for an early start in the marginal temperature range. Images: BÄCHLER

450 litres for three heads

For its three heads, the TRIDUSA triple-head lance requires 450 standard litres per minute. “In the marginal temperature range it can produce up to 21 cubic metres of snow per hour, which represents a water flow of 155 litres per minute. This volume is – in my view – unrivalled on the market,” Bruno Koch says. At 67 cubic metres of snow per hour, the maximum output of the two-stage lance is also impressive.

Efficiency in practice

Although there have repeatedly been temptations visually to jazz it up, these have been foregone in favour maximum efficiency with respect to material and energy consumption. BÄCHLER CTO Bruno Koch confirms this:

“We considered blue anodising the lance pipes in the company colours, which would undoubtedly look very handsome, but it would make absolutely no sense from the perspective of energy efficiency: it would make the design more vulnerable to freezing water. Function first and then design – so we stuck to raw aluminium efficiency.”

Conclusion

A look at the development history of BÄCHLER lances demonstrates that, from the outset, maximum energy efficiency is in the DNA for the Swiss manufacturer – and not just since the subject has been featured in the media.

“In the past, we have often been tested but we have always stood by our convictions. We are therefore all the more pleased that this thinking is also increasingly being practised in the ski resorts,” BÄCHLER COO Mario Koch emphasises.

Energy-efficient snowmaking is clearly becoming a game-changer.