The American Eagle in Colorado, Coppa Mountain. Foto: Peter Landsmann

Cities, SI Urban 1/2020

7 STRANDS FOR MORE ADVANTAGES

Teufelberger-Redaelli backs the 7-strand Solitec ®Max 7

2. March 2020

A few references for the Teufelberger Redaelli 7-strand cables

- Casa Cantoniera, Abetone (gondola lift Italy)

- MM50 People Mover, Pisa (People Mover Italy)

- KC 41 Crest – Alpe Ostafa III, Champoluc (gondola lift Italy)

- GD10 Oberalppass, Andermatt (gondola lift switzerland)

- American Eagle, Copper Mountain (Telemix USA)

- American Flyer, Copper Mountain (chairlift USA)

Ein Querschnitt des Solitec Max7®

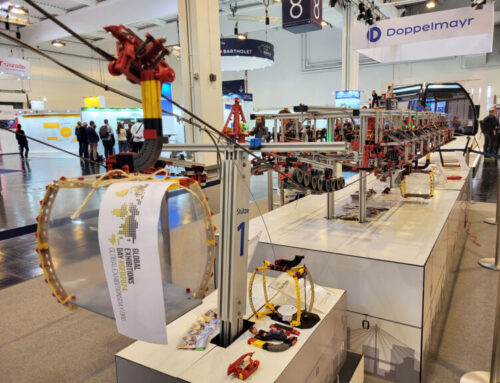

Greater precision and less wear when splicing the 7-strand Solitec ® Max7

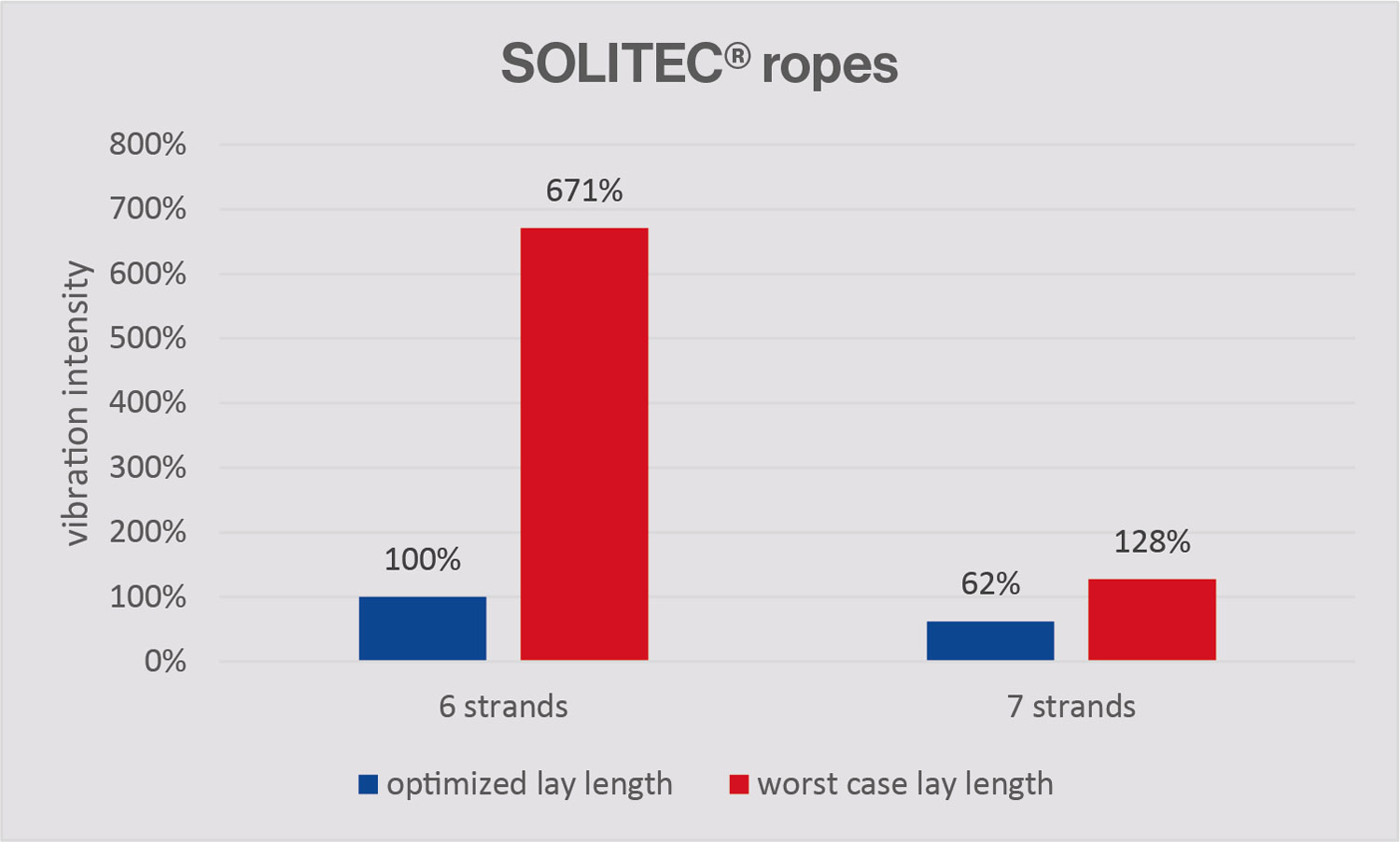

Die Steuerung der Resultate zwischen optimierter und "worst case" Schlaglänge ist bei dem 7-litzigen Seil signifikant geringer. Grafiken: TEUFELBERGER Holding AG

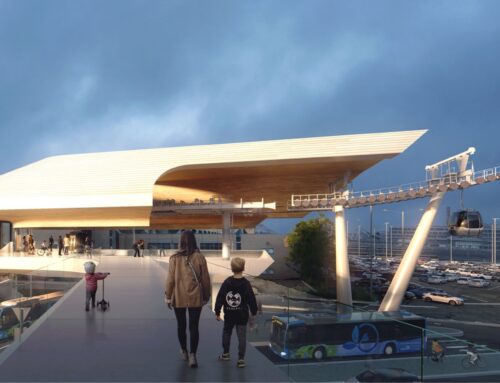

Comfort and smooth running pay off and Solitec® Max7 makes them possible

Alongside cleanliness and design, comfort and smooth running are two of the most essential properties noticed directly by users of a railway, whether urban or Alpine. Both are noticeably improved by the 38% reduction in vibration intensity from Solitec® Max7. Seven strands describe a “rounder” circle than six. The spaces between the strands are smaller and less deep, and they are held in a regular shape by the use of synthetic plastic profiles. The plastic profiles also prevent friction corrosion from strand contact.