Cities, SI-Urban

Protection for the urban cable car cable

Regular lubrication of a cable car cable in accordance with the maintenance and lubrication plan plays a central role in the functional safety of urban cable cars. There is no need to be a specialist here to know that irregularly lubricated systems are exposed to greater wear and therefore more susceptible to breakdowns.

MOTOREX Product Manager Markus Damm, who is responsible for the area of urban cable cars, provides information on correct application, for example such as here on wire cables.

Application tips

Wire cable lubrication with Cable Protect is generally recommended every six to twelve months.

“The intervals are affected by service life, travel speed, strain, drive and deflecting sheave radius, wind, temperature and general weather conditions,” Damm emphasises.

A number of points must be observed here. The cable, in dry, cold condition, must therefore be cleaned in advance with a wire rope cleaner. Solvents or detergents are absolutely off limits here, as they can destroy the existing lubricants and even damage the cores.

“Ensure that you lubricate only clean, dry cables with an appropriate cable lubricator,” the lubricating expert says. Lubrication should therefore take place only in fine, if possible warm, weather: there must be no rainfall for four to five hours after lubrication.

“Customers achieve the optimum effect with recurring lubrication,” Damm elaborates.

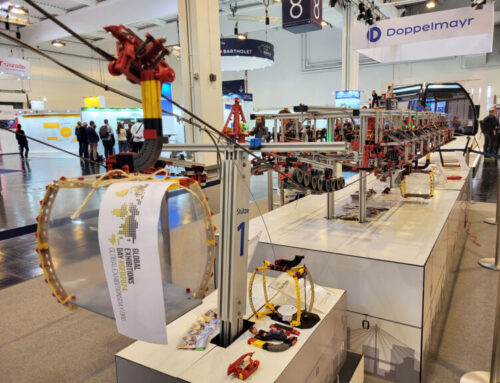

Circulating cables on urban systems can be lubricated with a cable lubricator.

The maximum volume of lubricant is 30 grams per square metre for stranded cables and 15 for supporting cables, Damm emphasises: “Be sure to observe the drying time here.”

Wire cable maintenance

In turn, special lubricant Cable Protect effectively protects all types of wire cable against the effects of weather and against wear. The product is diluted with a special solvent ex works. “This allows optimal, even application,” Damm highlights.

Once the solvent has evaporated, a thin, strongly adhesive, protective film forms, which is not sticky. Repeated deflection and strain on the cable results in abrasion of the countless wires in the cable.

“We developed Cable Protect specifically to reduce this type of abrasion. The product protects the cable comprehensively in extreme weather conditions, such as sun, rain, snow, heat and cold,” thelubrication expert says.

This ensures reliability – an essential criterion for urban cable cars that should be in operation every day. Ultimately, the population depends on them.

Lubricating the splice

The spray is additionally diluted so that it can be applied very easily and the splice can therefore be retreated regularly. As there is heavy strain on this area of the cable in particular, it is important to perform this work recurrently, Damm concludes: “This recurring work can have a positive effect on the service life of the wire cables.”