Cities, SI Urban 2/2021, Tourism

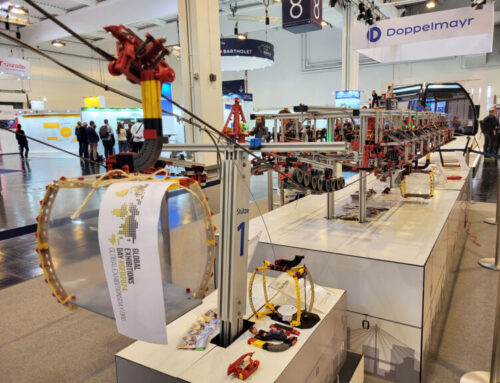

Cable car service – On urban cable cars in particular, relubrication is essential

Regular lubrication in accordance with the maintenance and lubrication schedule is vitally important for the functional reliability of urban cable cars. You don’t have to be an expert here to know that irregularly relubricated systems are subject to greater wear and therefore more susceptible to breakdowns.

MOTOREX Product Manager Markus Damm, who is responsible for the area of urban cable cars, provides information on the correct use of two key products.

3800 TS grease: keeps going

3800 TS grease from MOTOREX is a special EP long-life grease (EP = extreme pressure) based on a semi-synthetic base oil and thickened with lithium soap. The product is absolutely high-pressure stable and oxidation-resistant.

This makes it excellently suited to basic lubrication and relubrication of roller and plain bearings. It is designed for bearings that are exposed to large temperature differences and harsh operating conditions. This is the case in particular on urban cable cars, which operate for many hours within a short period.

Back to the grease: because of its excellent water resistance and exceptional adhesion, this lubricating grease can achieve a long service life. Consequently, the relubrication intervals can be significantly extended. The grease is compliant with specification KP2 N-30, in accordance with DIN 51502.

Tips for use

But how exactly do urban cable car operators use 3800 TS grease? “Essentially, regular maintenance in accordance with the lubrication schedule from MOTOREX and the cable car manufacturer is compulsory, as is monitoring of the maintenance,” Damm says.

The grease should be stored at room temperature, and the grease nipple and equipment must always be cleaned before lubricating. “Furthermore, you shoud always keep the area around the central lubrication systems clean,” the expert emphasises.

The lubricating points must always be greased until the emergence of clean grease is visible. “The Excess grease can be wiped off with a clean cloth,” Damm says.

Wire cable care with Cable Protect

Special cable lubricant Cable Protect effectively protects all types of wire cable from weathering and wear. The product is diluted with a special solvent ex works. “This allows optimal, even application,” Damm emphasises. When the solvent evaporates, a thin protective film forms, which adheres well and is not sticky.

Repeated deflection and load on the cable cause friction of the countless strands present within the cable. “We developed Cable Protect specifically to reduce this type of friction.

The product provides comprehensive protection for the cable in the case of extreme weather conditions, such as rain, snow, heat and cold,” the lubrication expert says. This ensures fail-safety – a critical criterion for urban cable cars that need to be operational every day.

Tips for use

Relubrication with Cable Protect is generally recommended every six to twelve months. “The intervals are influenced by operating period, travel speed, load, radius of the drive and deflecting pulleys, wind, temperature and general weather conditions,” Damm emphasises.

The cable can be cleaned with a cable brush only when dry and cold. Solvents or detergents must be avoided here. “Ensure that you lubricate only clean and dry cables,” the lubrication expert says.

Relubrication should therefore take place only in fine and, if possible, warm weather; there must be no precipitation for four to five hours after lubrication.

“Customers will achieve optimal effect with slightly diluted Cable Solvent lubricant,” Damm elaborates. The maximum quantity of lubricant is 30 square metres for strand cables and 15 grams per square meter for supporting cables,” Damm concludes. “Ensure that you observe the drying time here!” ts