Cableway & Technology, SI World 1/2020

INAUEN-SCHÄTTI BLASTING IN BERWANG: AVALANCHE MASTS REPLACE BLASTING CABLE CAR

The systems replace Austria’s longest blasting cable car, which guaranteed avalanche safety over a distance of four kilometres for over 40 years. “With the cable car, however, only one shot per run was ever possible.

In fresh snow, we needed over two hours for blasting,” Bergbahnen Berwang Managing Director Gernot Falger reports. By contrast, with the LM32 blasting masts from INAUEN-SCHÄTTI, this work can be done in five minutes.

“In addition, blasting with the avalanche masts is significantly safer,” Falger says. As INAUEN-SCHÄTTI had previously installed five casting masts of type LW2700 in Berwang, the choice was easy for the people responsible: “One mountain – one manufacturer.

INAUENSCHÄTTI is competent and offers good service. We are very satisfied,” the mountain railway boss says. Although the blasting mast allows 32 shots, Bergbahnen Berwang had the installations configured at 16 shots.

“We have a maximum requirement of only 12 to 15 shots but we could expand the number of charges at any time,” Falger justifies the decision. In the 2019/2020 winter season, they have blasted twenty times to date in Berwang – with highly satisfactory results every time.

About the LM32 blasting masts

The new development of the LM32 Avalanche Trigger meets a clear customer need. Various customers operate pistes with avalanche paths in which blasting has to take place significantly more often for safer pistes.

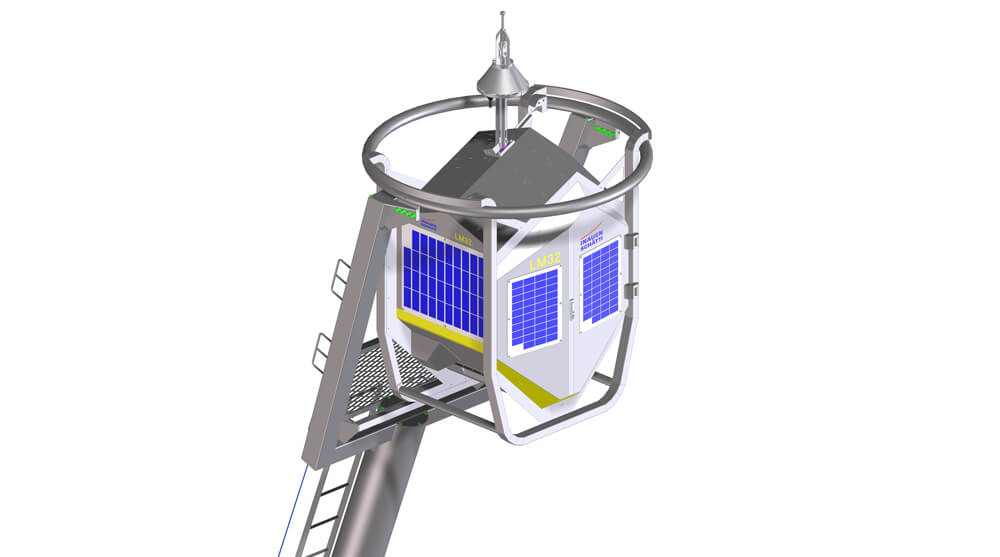

However, road safety also often requires a greater number of blasts to ensure avalanche safety. Avalanche Trigger LM32 represents an avalanche mast with a maximum capacity of 32 blast charges for remotely controlled artificial avalanche triggering.

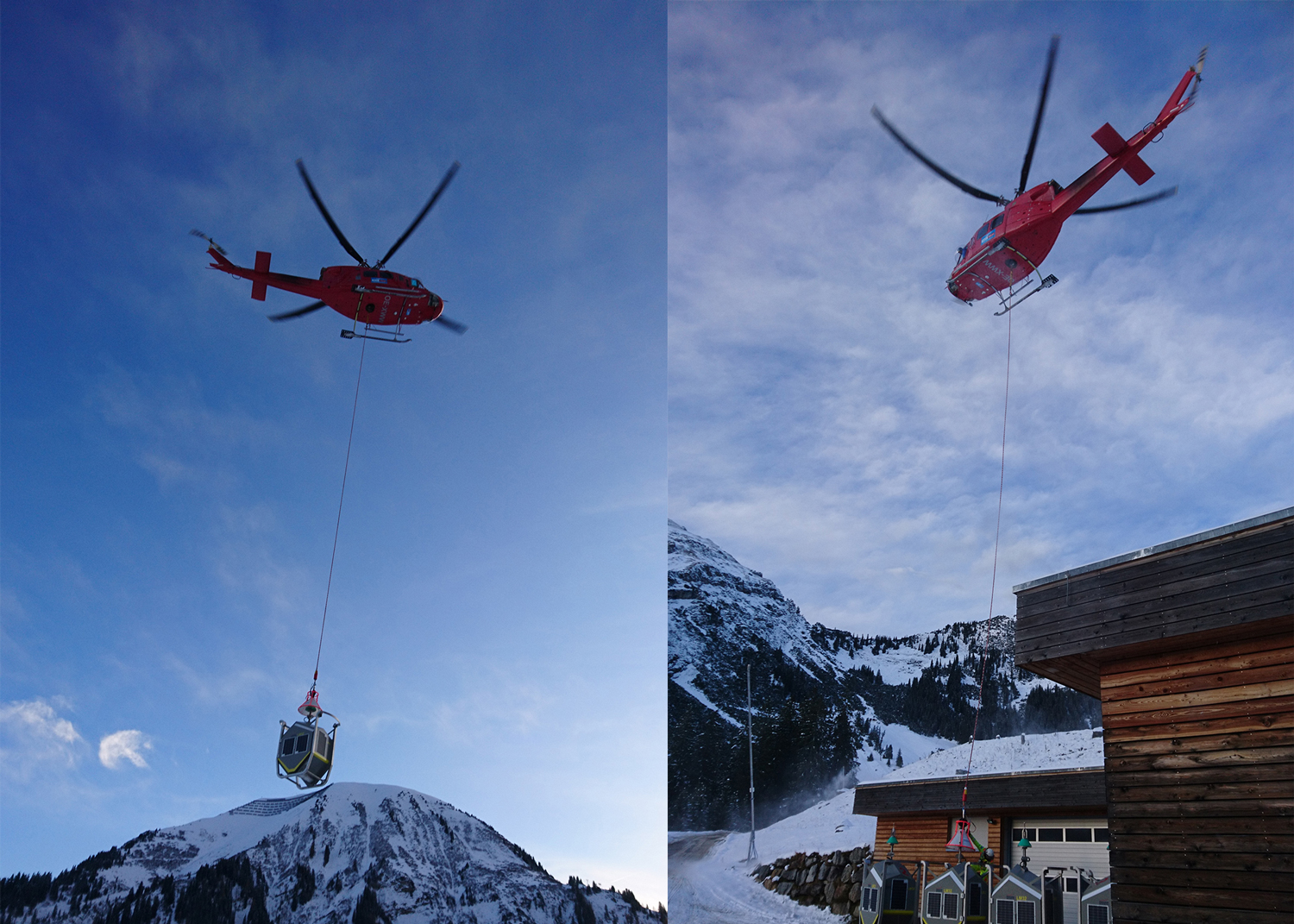

The LM32 casting module can be placed directly on the mast by helicopter. Via computer, tablet or smartphone, the blast charge is then ejected as required using the ATMS virtual control centre. ATMS is a cloud solution; all that is needed is the ability to access the server.

The casting box is charged conveniently in the valley below and the S-LOAD charge system simplifies the process substantially. Using the automatic “Auto-Loc” helicopter coupling, the LM32 casting box can then be flown into the mast ring.

S-LOAD blast charge

The newly developed and patented S-LOAD blast charge for the LM32 Avalanche Trigger blast mast impresses substantially with a mechanism that brings together the explosive and the detonator only shortly before blasting. During transit and storage in the casting box, they are stored separately.

The S-LOAD blast charge is split into two parts: the top part contains the coil body and ignition sequence (blast detonator, safety fuse and detonator capsule number 8), whilst the blast charge and explosive (explosive material and detonating fuse) are positioned in the bottom part.

In transit and storage, the explosive and detonator are separated by a certified housing. When the detonator is activated, it is guaranteed that the explosives cannot be injected.

ATMS – The virtual control centre

After arriving in the ring, the position of the box is determined by GPS and other sensors and it is activated to be ready for triggering. The system now runs on standby and can be activated when required, and the five-kilogram blast charges can be ejected by remote control on a computer, tablet or smartphone.

The new, web-based ATMS control allows many new features and at the highest level of safety. This is information that Gernot Falger from Berwang can confirm: “We blast with our smartphones. The time saving along with greater occupational safety is huge.”