Maintenance & Service, SI-Alpin

Iced cable cars: causes and countermeasures

Formation of ice

When moist air cools down, some of the water condenses, leading to phenomena like rain or fog. On cool surfaces such as buildings, windows, and cables, water also settles, and when temperatures drop below freezing, it forms ice.

The ice on cables can become large and heavy: frozen cables hang lower and strain the tensioning equipment. Ice falling suddenly can lead to strong vibrations and dynamic load peaks. Potential risks include the release of a cable from the pulley system, the crossing of suspension cables by traction cables, or damage to classic tension weights upon impact with the ground.

The ice build-up can also block the system if motor power and torque are insufficient to release the ice. On the route, frozen rollers can be damaged when the system frees itself.

Types of ice formation

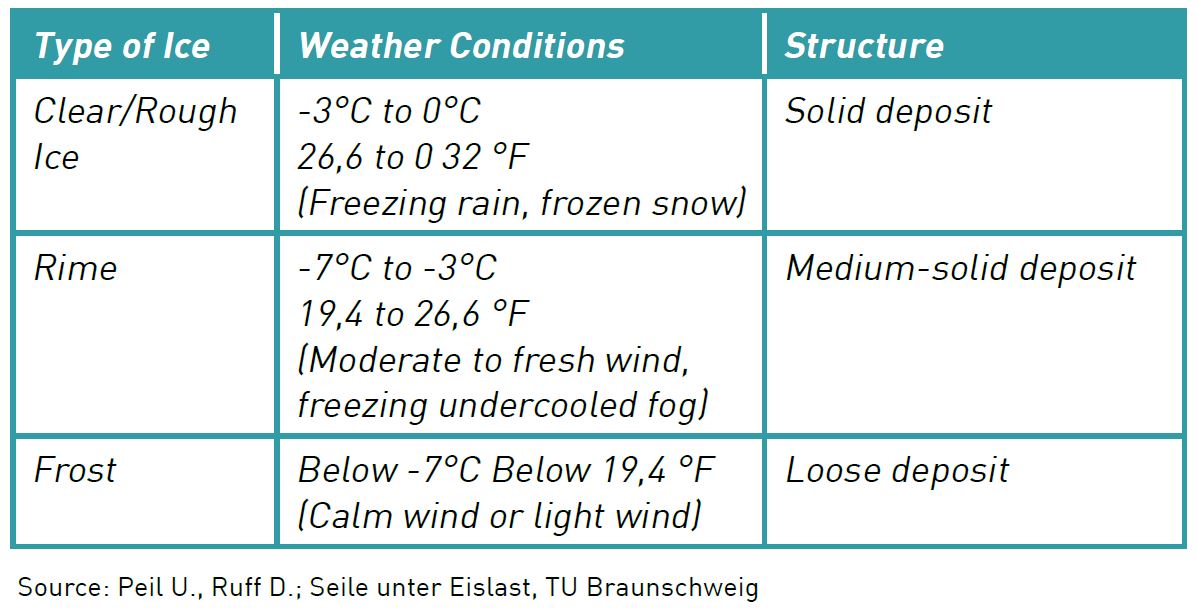

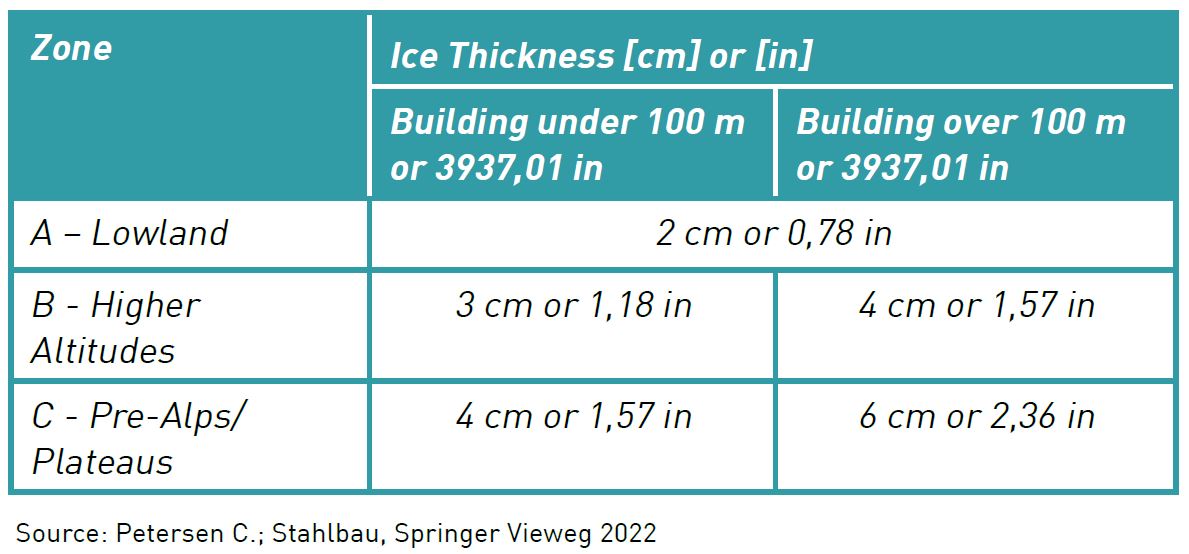

Ice isn’t always the same: its structure, density, and appearance can vary based on weather and location. The following types of ice may form depending on the weather conditions:

At higher altitudes and on plateaus between 70 0 to 1,200 meters, ice formation can be significant. Regions in the north, such as the first alpine ridges or mountain areas with large adjacent bodies of water, are particularly affected. Literature suggests expected ice thicknesses based on location:

Therefore, the potential additional ice mass is also considered in the calculation of cable cars according to EN 12930.

Measures against ice build-up in operations

The industry shares tales of past methods or impressive photos on social media of de-icing operations. Unfortunately, the effectiveness of these methods is often not well documented:

- For circulating systems or mountain cable loops, some operators drive slowly at night to prevent ice formation. Some cable cars have been equipped with smaller drives to operate at low power for this night-time operation.

- For aerial tramways, ice is typically broken off using ice scraper plates and special pulley bodies on the drive system. Years ago, attempts were made with a system that used artificially created vibrations to shake the ice off the cables at the push of a button. In Sweden, helicopters are sometimes used to break the ice from the cables by swinging a tree trunk against the suspension cable.

But what works best in practice? We spoke with Bernhard Thoma, Deputy Operations Manager of the Zugspitze Cable Car in Germany, who has experience managing ice on one of the world’s most spectacular cable cars. The Zugspitze cable car spans nearly 4.5 kilometers in length and a 2-kilometer elevation difference.

De-icing in Åre with the help of tree trunks and helicopters. © FB-Screenshot/Are

Zugspitze‘s approach

At the Zugspitze, a staff member stays overnight on the mountain. This allows stations to be controlled and cleared early, and cabins to be repositioned. In emergencies, a technician can come via the cogwheel railway through the tunnel to assist with the glacier cable car’s start-up.

When the cable cars are iced over, the system is manually moved back and forth in the cabin intake area until all pulleys are free to move again. Additionally, foldable ice scraper systems are mounted at the Zugspitze’s mountain station, which can be mechanically locked and electronically monitored.

During operation, vehicles cannot enter the station, and the opposing track is also blocked to avoid confusion in work zones. The incoming traction cable must be de-iced at the mountain station, over a 300-meter stretch until the first cable carrier.

Best-Practice

Ice scraper (left) and white hard plastic roller on the drive system of the Zugspitze cable car.

Keeping the cable car in motion

The most challenging situation arises when it rains below the summit and snows at higher elevations. Water from the drive system can freeze on the station rollers, making them freeze at the mountain station.

Therefore, the roller profiles were modified to increase the distance from the station’s steel parts. Also, the cable car is intentionally moved slower (8 m/s) on such days to maintain a 15-minute interval and ensure nearly continuous operation. Just 30 minutes of downtime is enough for the rollers to freeze.

Experts

SI author Konstantin Kühner (left) with Bernhard Thoma from the Zugspitze cable car.

Practical de-icing at the valley station

At the valley station, de-icing is easier. The traction cable can be gently nudged with the foot to loosen the ice, clearing the path to the first cable carrier. The more snow is removed before the station, the less needs to be cleared later.

Ice scraper systems are installed on the cabins themselves to clear the suspension cables, with a 5-6 millimeter gap. Each drive unit also contains

cebreaker rollers made of hard plastic.

Experience has shown that the rollers are no longer mounted at the front of the cable car to avoid ice hitting the cabin‘s front windows. After breaking the ice, the cabin’s roof still needs to be manually cleared.

Rustic but gentle on the cables

For slope security, even explosive cable cars must be kept in motion. This process is more rustic: moving forward and backward with the help of ice scraper plates on the windows to remove most of the ice.

Sometimes, wooden beams and brooms are used to tackle stubborn ice. Preventatively, little can be done to stop ice formation, except to operate the system. However, with thoughtful planning and practical, proven devices and strategies, rapid and cable-friendly de-icing is possible.

Autor: Konstantin Kühner