Maintenance & Service, Specials

Motorex cable protect: The right care is crucial

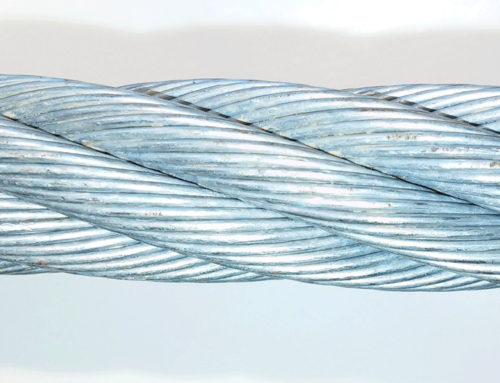

For cable cars to function reliably in all weather conditions, regular maintenance is essential. For cable car ropes, this means regular lubrication according to a specific maintenance and lubrication schedule.

The frequency of lubrication depends on operating time, speed, load, radius of drive and deflection pulleys, wind, temperature, and weather conditions. Typically, lubrication intervals range from six to twelve months.

Simply spray

The handling of CABLE PROTECT is incredibly easy.

Special development: also for the splice

Choosing the correct lubricant is crucial during the lubrication process. Swiss lubricant specialist MOTOREX offers CABLE PROTECT for cable car ropes.

This lubricant was specifically developed for wire ropes and is suitable for ropes of all types of cable cars, cranes, as well as bollards or reels for the hauling rope reserve. Even the splice, a critical point in the rope, can be excellently treated with this lubricant.

To increase the lifespan of the rope

Bending or loading the rope leads to friction between the cable car wires – CABLE PROTECT was precisely developed for this specific requirement. Additionally, the lubricant efficiently protects against weather influences and wear, thus increasing the rope‘s lifespan.

The product is pre-diluted with a special solvent, allowing for easy application. After the solvent evaporates, a thin, non-sticky, and highly adhesive, water-repellent protective film forms.

Proper application

Before starting the lubrication process, the rope should be cleaned while dry using a rope cleaner. To avoid damaging the existing lubricant film or inserts, solvents and detergents are absolutely prohibited for this cleaning process.

The maximum amount of rope lubricant to be applied afterward with a suitable rope lubricator is approximately 30 grams per square meter for strand ropes and 15 grams per square meter for hauling ropes.

Ideally, application should be done at temperatures above +10°C. Subsequently, the rope must be allowed to dry properly for several hours to half a day – hence, lubrication is recommended only in fair, preferably warm weather.

The advantages of cable protect at a glance

- Prevents corrosion and internal wear of wire ropes

- Biodegradable

- Lengthens the lifespan of the wire rope

- Compatible with the most common rope pulleys and drive wheels

- Compatible with common rope base lubricants

- Economical application, only 1 to 2 times per year

- Available in different container sizes, as a 500 ml spray or in a box containing 6 x 500 ml sprays.

- For more information, visit: motorex.com/alpine