Cableway & Technology, Maintenance & Service

Rapid response during revision

Betelberg is a part of the Adelboden-Lenk ski region in the Bernese Oberland (Switzerland) and the Alpine culture mountain for locals and guests.

The 4-seater chairlift with the Wallegg- Mülkerblatten route covers a length of 1,461 metres. It was built in 1989 by the manufacturer Städeli and since this time it has been transporting 1,800 passengers per hour to its mountain station on 1,936 metres.

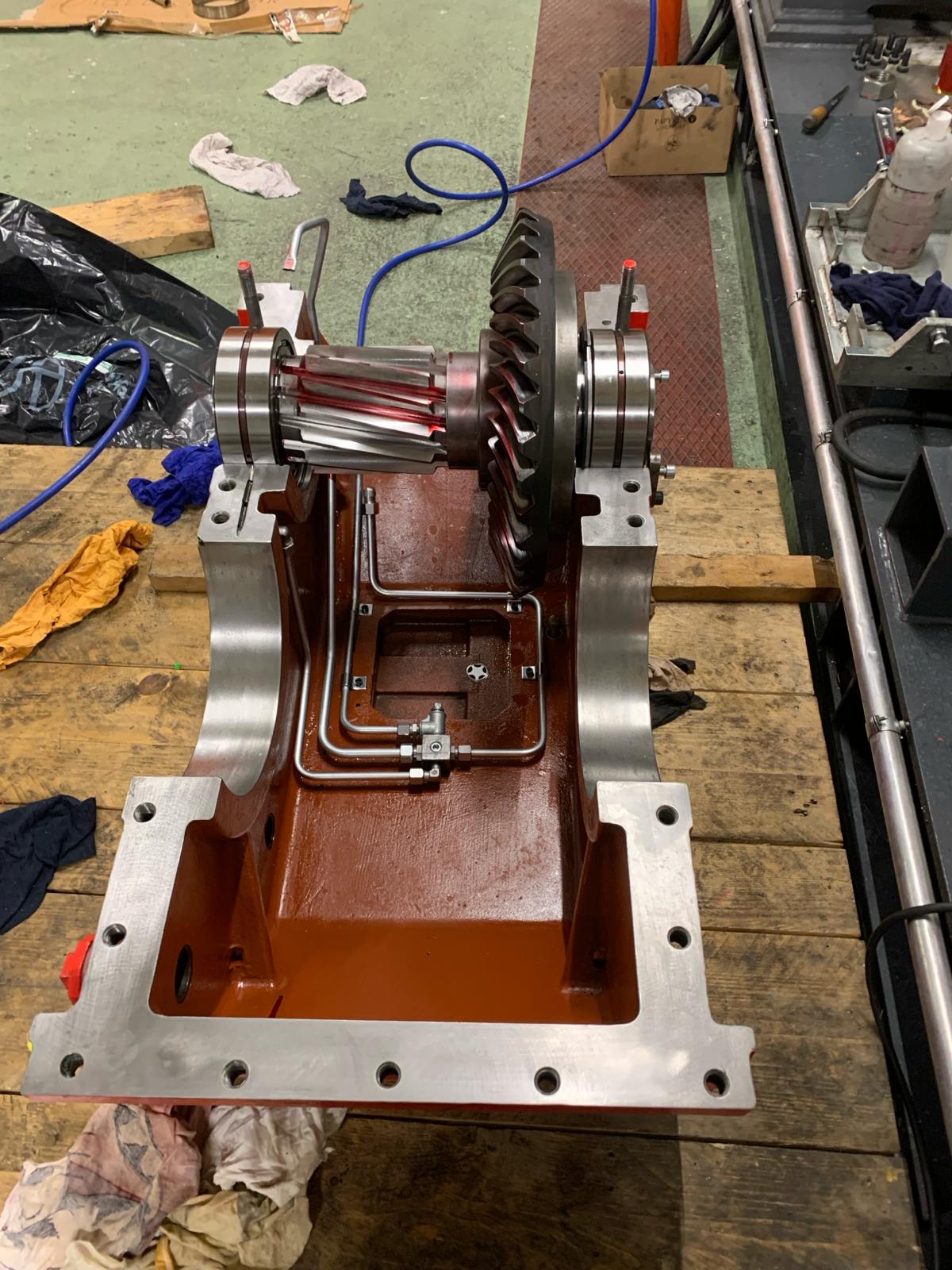

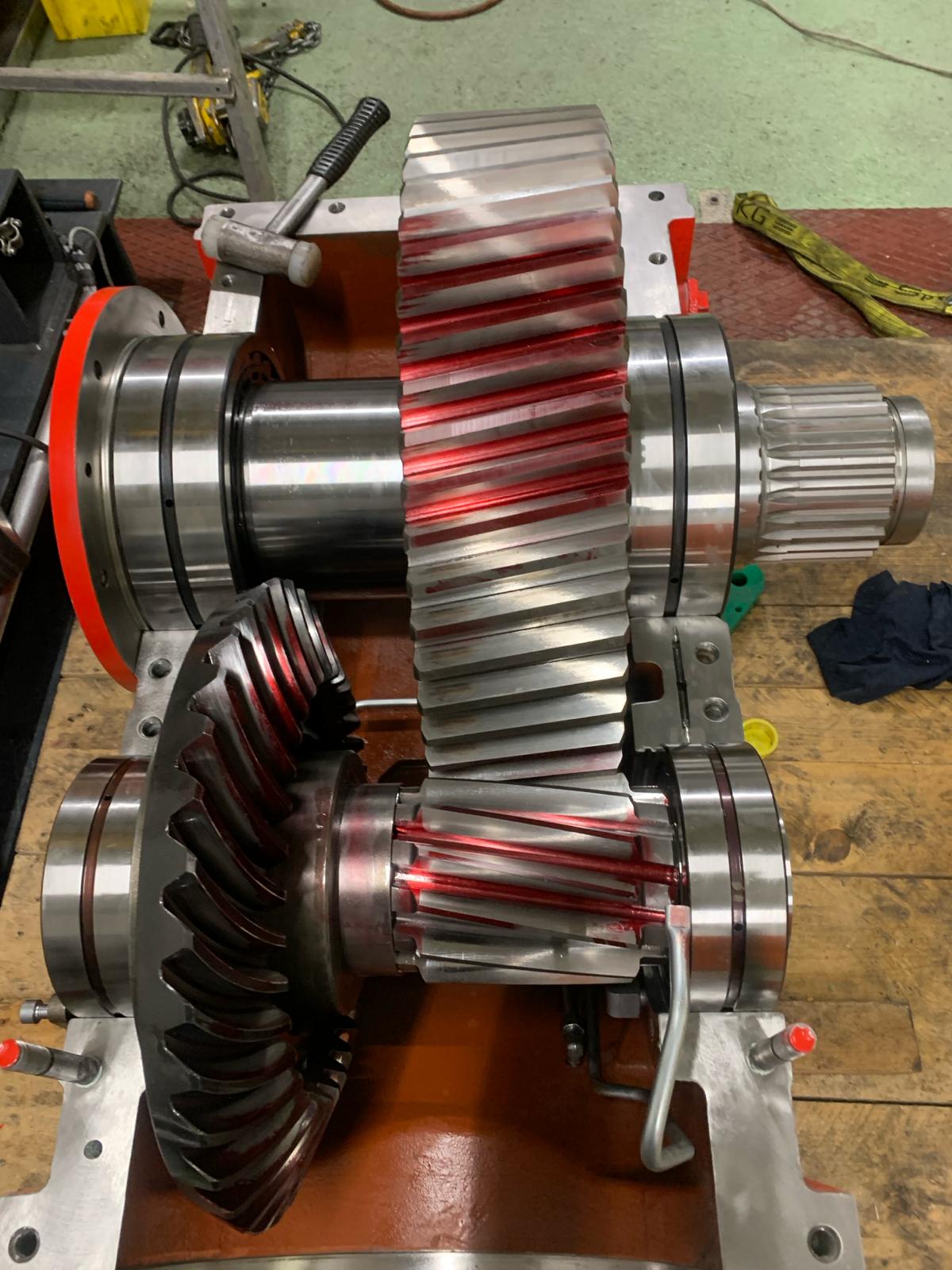

During a standard inspection of the chairlift, KISSLING AG discovered a defect in the gearbox in section 2. The company carried out the gearbox overhaul for the customer, Bergbahnen Adelboden-Lenk AG.

The overhaul went smoothly overall, but when the gearbox was commissioned, it was discovered that there was sealing compound in one of the cooling channels. This presented an unexpected challenge, but one that had to be addressed immediately to ensure the gearbox functioned perfectly.

Quick and efficent

Thanks to KISSLING AG‘s quick response and commitment, the gearbox was immediately disassembled again on site and the technical issue thoroughly removed. This unforeseen incident did not lead to any significant delays in the overall process, as KISSLING AG implemented the necessary measures quickly and efficiently.

As a result, the revised gearbox could be put into operation by the customer on schedule and in perfect condition. “We would like to thank the KISSLING AG for their professional approach and quick response in this matter, which led to a successful solution to the problem,“ says Technical Manager of Betelberg Klaus Linder.

Klaus Linder

Technical Manager Betelberg, Adelboden Lenk AG

“During vibration measurements on the gearbox of the Wallegg-Mülkerblatten 4-seater chairlift, we realised that it needed to be overhauled. We therefore turned to KISSLING AG. There was a incident in production during the repair, but the company reacted in an exemplary manner and the problem was correctet at the station. Overall, I am very satisfied with the work that the KISSLING AG carried out on the gearbox of the 4-seater chairlift!“

Technical Data

4-seater chairlift Wallegg-Mülkerblatten

| Capacity | 1,800 p/h |

| Travel speed | 5 m/s |

| Capacity per chair | 4 |

| Height bottom station | 1,585 m |

| Height top station | 1,936 m |

| Height difference | 352 m |

| Inclined length | 1,461 m |

| Travel time | 5,20 min |

| Drive position | top station |

| Tension position | bottom station |

About KISSLING AG

The company KISSLING AG settled in Switzerland is a leading provider of innovative gearbox solutions. It develops, designs and manufactures special gear units for the highest demands and a wide variety of applications.

Many cable cars, roller coasters, cement and sugar mills, paper machines, extrusion plants, agitators, test benches and power stations are equipped with gearboxes constructed by the KISSLING AG.

As a medium-sized family business, the company can fully utilise its strength of flexibility and develop and build individual drive concepts for its customers. Products designed by the company are characterised by high operating safety, above-average service life, compact design, high power density, smooth lownoise running and optimised efficiency.