Cities, SI-Urban

The instruments for the recovery of urban cable cars

As the spans of urban cable cars are often very large and the cable spans are very flat, special equipment is required for rescues. In the city, rescuers are helped neither by gravity – as in the mountains – nor by the distance between the support and the gondola.

To get to the gondola quickly, rescue squads here must move themselves along by winch or cable rescue carriage

Standard device

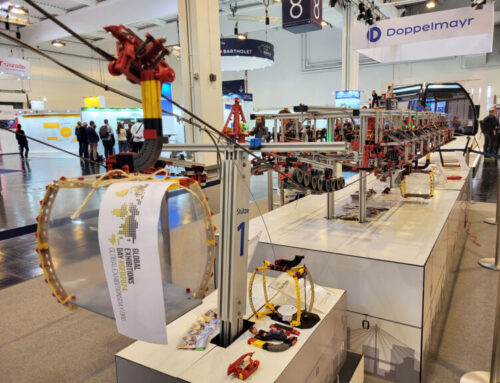

“Our SS1 self-driven cable rescue carriage is particularly suited to this case. With the motorised equipment, the rescuer can get to the gondola independently and without assistance from a second rescuer,” the rescue expert Florian Immoos reports.

Even gradients up to 20° or 36%, such as often occur on urban cable cars, are no problem. With special additional equipment, the rescuer can then gradually pick up passengers. The SS1 from IMMOOS is therefore extremely popular in the ropeway industry and has already been in use more than 2000 times.

There are now special cable carriages for demanding operations.

Special solution

Only recently, IMMOOS launched a new model on the market: the SS20 AWD. This was designed mainly for applications with greater stress and for travelling up mountains.

The SS20 AWD is even more hard-wearing than the other models and has better traction on the cable, which results in better transmission of the power from an external drive to the cable. In turn, this means more economical operation.

Innovative drives

It is not only the cable carriages that are subject to continuous optimisation; IMMOOS is also innovative with drives and invests a great deal of time and money in the development of new products.

As well as the classic drive using a cordless drill/screwdriver, the 4-stroke motor drive has proven itself over many years. However, as a result of the ever-greater demands, the motor was increasingly reaching the limits of its performance.

IMMOOS therefore developed an electric motor, which meets significantly higher demands and – thanks to a more powerful battery – displays a range that is many times greater. For slightly smaller demands, IMMOOS offers a cheaper alternative with an enhanced cordless angle drill, which can be flange-mounted on the cable vehicle.

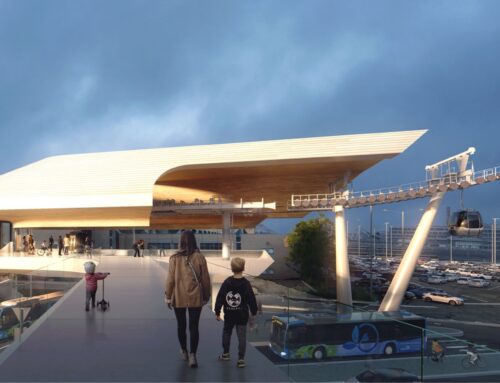

The recovery teams of urban ropeways are trained by IMMOOS.

Well-designed brakes

Nonetheless, the most important criterion – safety – must not be neglected amid the ever-growing demands. This is why IMMOOS has also developed a new type of safety brake, which can be (retro)fitted on cable vehicles and running gear for additional safety.

The safety brake is designed for use mainly on long and steep cable sections and for moving passengers along the cable, when working with no redundancy.

Training, concepts and service

But how are the cable carriages operated? This is what operators of urban ropeways learn during the training courses that IMMOOS conducts on site.

The Swiss company also creates complete recovery concepts, sells personal protective equipment for rescuers and offers all-round carefree packages, which also include the control and maintenance of the equipment includes.