Maintenance & Service, SI World 2/2020

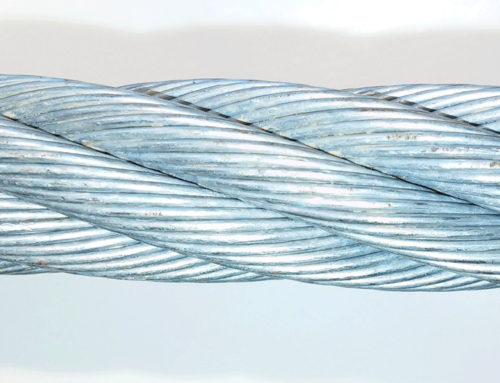

Jacob rope systems: When ropes talk

Visual inspection of ropes is an important part of the operational checks and maintenance of a cable car, which may take some time. Indeed, in the visual inspection, it is essentially a good sign if no damage is visible on the rope.

With a little patience and care though, if a broken wire is found, it is worth looking more closely than merely enough to distinguish between broken and intact cables. With the knowledge of how a wire fracture has occurred, it is possible e.g. to determine maintenance work and inspection intervals in a better way.

By responding in time, the best possible use can ultimately be made of the availability and service life of a rope. The shape of the fracture surface can provide valuable clues here with respect to how the wire fracture has occurred.

Below, the rope experts from JAKOB ROPE SYSTEMS provide a brief overview of the key cable fracture shapes and their causes.

Classic appearance of a fatigue fracture in a cable car rope (left) and the flat fracture surface under the microscope. Images and graphics: JAKOB ROPE SYSTEMS

The crack grows every time it flexes

The classic fatigue fracture occurs as a result of constant flexing of cables as they run around station sheaves. Even slight lifting of the rope under a grip in the case of ski lifts or fixed-clamp chairlifts on the sheave causes flexing – which is why the vehicles are regularly relocated depending on operating hours.

Fatigue is now understood to be the gradual hardening of the material, especially on the surface. Over time, it begins to crack open on a microscopic scale. Every time it flexes, this crack extends into the material – until the wire breaks.

From the fracture surface of a wire, it is possible to see how the crack has extended into the wire. Like the growth rings of a tree, a flat part can be seen on the fracture surface, which has developed perpendicular – as if cut – to the wire axis. The weakened remaining cross-section of the wire fails as an overload fracture, which has a chaotic shape.

Cables behave like marathon runners

If ropes become fatigued in ongoing operation, they develop wire fractures at an increasing rate over time. The fatigue process of the wires in the rope can be compared with the fatigue of runners in a marathon. All runners experience a challenging, energy-sapping distance; the closer they get to the end, the more there are who give up as a result of the strain.

The many wires in a rope become fatigued and break more quickly the longer the rope has been strained by constant flexing and the nearer it is to the end of its service life. The fact that more and more wires fail towards the end of the service life or durability of the rope is referred to as an exponential development.

The development is actually very easy to predict if several magneto-inductive rope tests and the respective number of wire fractures are already available. If the trend follows a curve, the rope will continue to follow this curve in the future in most cases.

This trend is a key factor to determine the time of the next rope inspection, as the inspection periods for a rope must be shortened as the operating age increases.

Various fracture shapes

The overview shows several additional examples of characteristic shapes of fracture surfaces and their significance. A cup-plate fracture occurs if wires have been forcibly snapped. Such fractures can be found e.g. on snapped tensioning ropes or snow groomer winch ropes.

This fracture shape does not occur as an individual fracture in an otherwise intact rope. Chisel-shaped fractures occur as a result of wear, e.g. if ropes run over steel sheaves or have come into contact with a hard structure during movement.

Shear fractures are indicative of serious twisting of the rope or strands, which has resulted in shearing of the wire. So-called irregular fracture surfaces occur if many forces and powers act on a rope simultaneously. Severe buckling, a kink or a rope tangling and jamming on a structure can result e.g. in such fracture shapes.

Percentages rather than absolute numbers are critical

In the standards and regulations for cable cars, the assessment criteria are specified not as a number of wire fractures but rather as a percentage of the “theoretical cross-section loss”.

When counting broken wires and assessing a rope, it is therefore very important to know what percentage of the total rope crosssection is represented by one broken outer wire in this specific rope design. In the table below, these outer wire percentages are specified for classic rope designs.

New experiences time and again

The information shown here represents only an excerpt from the many different rope defects and influences. Experience teaches us that something new can always emerge when it comes to ropes – and in the end, that is also what makes handling them so interesting. If you find something that you have not seen before or about which you would like a second opinion, the rope experts from JAKOB ROPE SYSTEMS are happy to help. ts