Maintenance & Service, SI World 2/2020

Kissling: Feeling motion – even in times of crisis

Globally, we are currently living in a situation where, in many places, service technicians are not allowed to go to customers. This is also affecting KISSLING AG. The spare parts business is less severely affected, as spare parts can be delivered relatively promptly by post or carrier – the technicians who replace spare parts, unfortunately not.

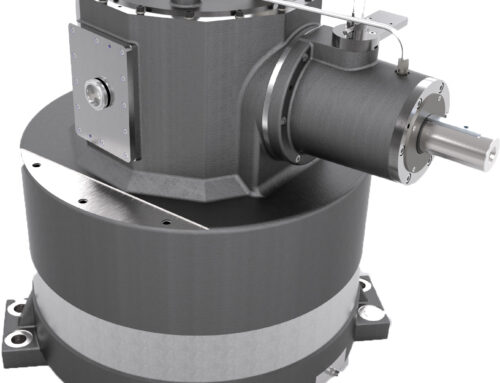

“We therefore want to help our cable car customers internationally. Our fitters overhaul all types of gear unit in-house, regardless of manufacturer and restore them to almost new condition,” Head of Marketing Roman Siegfried reports. With decades of experience in gear unit construction, KISSLING is the right partner for this.

Detailed assessment of components is standard for KISSLING when overhauling cable car gear units. Photos: KISSLING

All-round package in difficult times

“If they are designed properly and maintained carefully, gear units can perform their function faultlessly for many years. However, overload, extreme conditions and other factors can cause wear or defects – with any gear unit from any manufacturer,” the Head of Marketing emphasises.

Since the company was founded, KISSLING has therefore operated a welldeveloped service department and kept a broad stock of spare parts. The range of services from the Swiss company is very large here and as an all-round package, it can offer certainty, particularly during the coronavirus crisis.

Specifically, KISSLING takes care of transporting the gear unit, cleans it thoroughly by sandblasting, assesses the component, replaces bearings and seals, checks shafts and cog parts, paints the housing and produces an installation report. As such, the Kissling Service Centre performs the complete range of services for everything to do with gear units – not only for in-house products but also for other products of all brands.

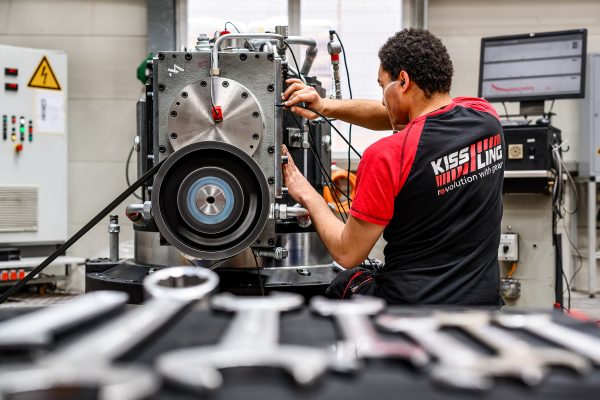

Well-trained experts with many years of experience provide fast, efficient and professional service, such as can be offered only with the expertise from over ninety years of gear unit construction.

All gear units undergo intensive checking on the company’s own test rigs.

Sandblasting facility even for large gear units

Cleaning in the KISSLING AG sandblasting facility lies at the heart of any gear unit overhaul. This five-metre-long by fourand- a-half-metre-wide cleaning box offers space for a small car and is situated in the production building of the Swiss gear unit manufacturer in Bachenbülach near Zürich.

The sandblasting facility cleans dirt and paint residues from all gear units that are sent in, to allow beautiful, comprehensive repainting. Sandblasting is possible for parts with a size of two by three metres, maximum dimensions of 220 x 350 x 300 centimetres and a maximum load of six tonnes.

KISSLING maintains a broad stock of spare parts.